An IoT and ERP platform to help SMEs monitor and optimise production

Enterprise

Dio Smart Ing SH.P.K

Presentation of the enterprise

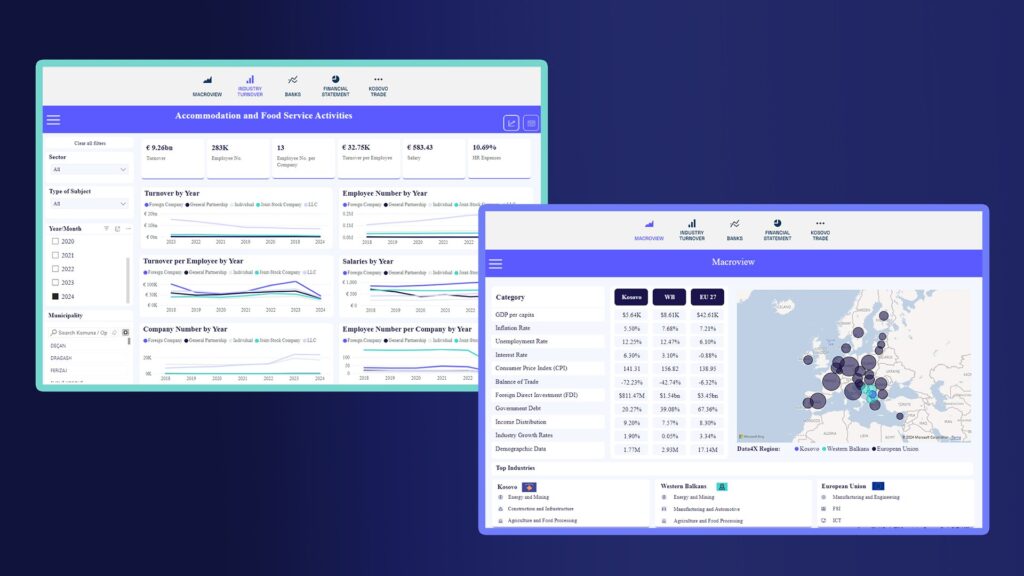

Founded in 2020, Dio Smart develops affordable smart factory solutions that combine IoT sensors, PLCs, and the DIO-IOT™ software to help manufacturers in Kosovo monitor performance, reduce downtime, and improve efficiency.

Amount of co-financing

EUR 119,910

- Kosovo

- 2025

- Ongoing

Challenge

In Kosovo, most manufacturing companies operate with limited automation and low data visibility, relying on manual systems that lead to frequent downtime, energy waste, and inefficiencies. SMEs cannot afford expensive international smart factory solutions, leaving them behind in digital transformation.

Innovative solution

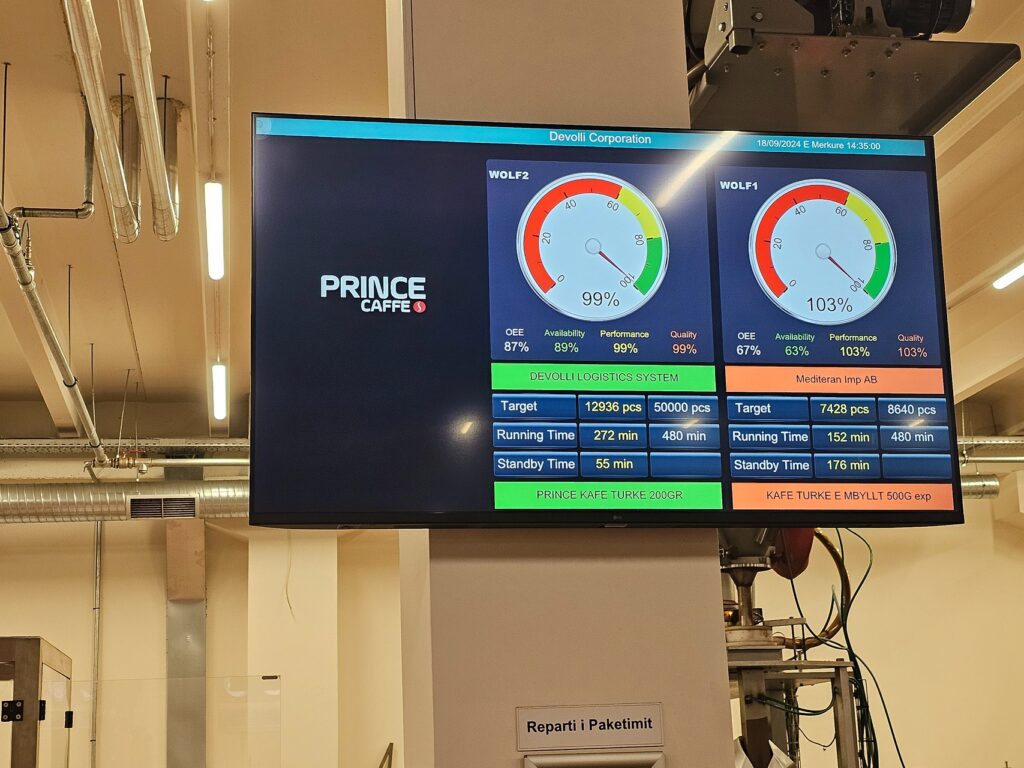

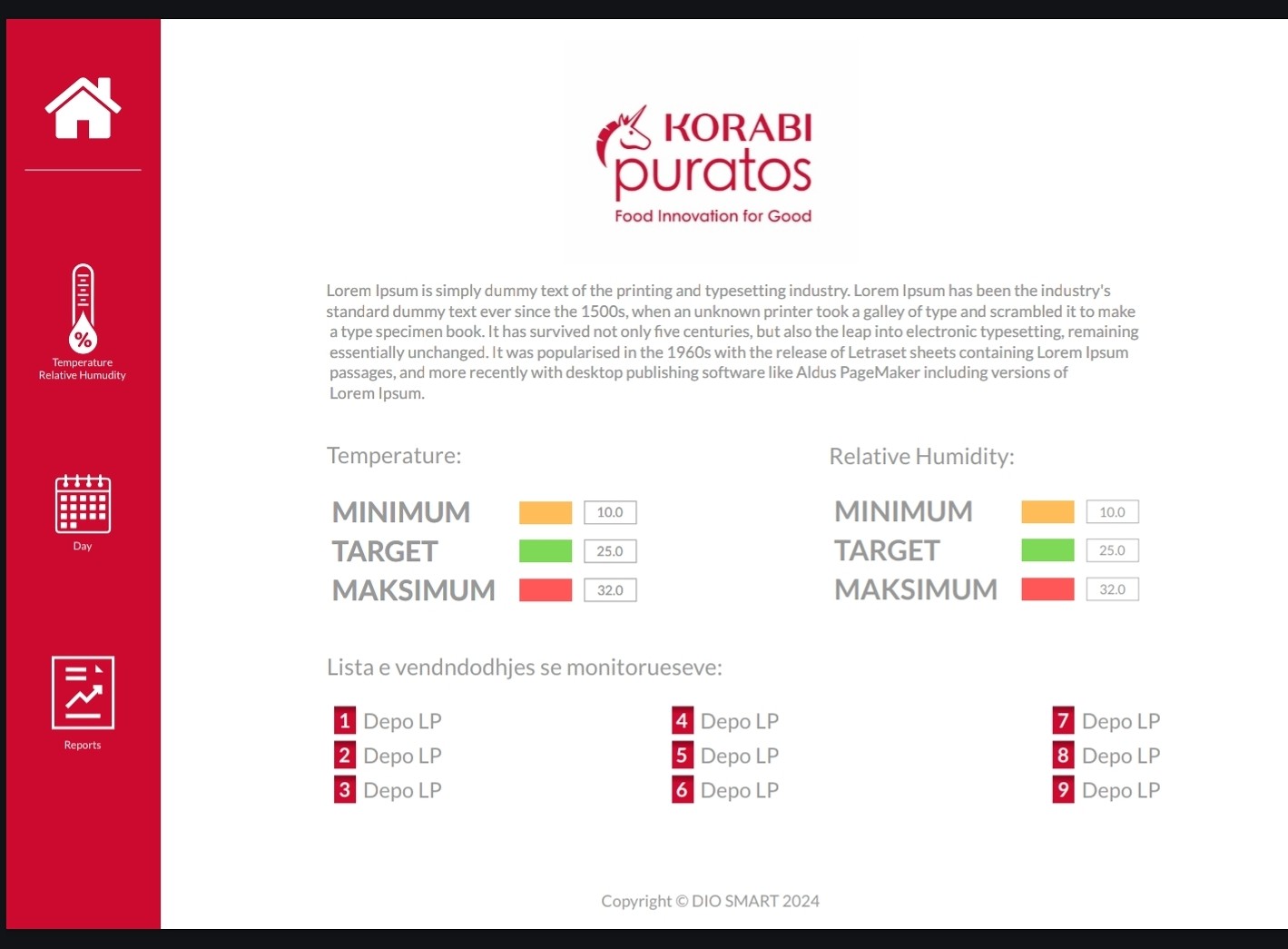

Dio Smart addresses this challenge by offering an affordable, locally tailored IoT-based solution that enables manufacturers to monitor performance, reduce waste, and improve productivity in real time.

It introduces Kosovo’s first modular smart factory system that integrates IoT sensors, programmable logic controllers (PLCs), and the DIO-IOT™ software platform to help manufacturers track performance and efficiency in real time. The platform provides automated monitoring of machine productivity, downtime, and energy consumption, while future upgrades include ERP integration for seamless data flow across operations. Through a flexible and affordable subscription model, Dio Smart makes advanced digital manufacturing tools accessible to SMEs, driving industrial modernisation and sustainable production in Kosovo.

Impact

- Improved productivity for 8 additional manufacturing companies, by using the Dio Smart IoT system

- Adoption of Dio Smart’s monitoring and automation solutions by 17 new clients

- 30% average increase in customer productivity achieved through real-time data monitoring (from 5% baseline)

- 20% improvement in energy efficiency per unit of production achieved across client factories (from 5% baseline)

- 20% reduction in average machine downtime through continuous performance tracking (from 5% baseline)

- 5 new jobs created

- 4-stage CO₂ monitoring dashboard designed, developed, piloted, and launched for client use

Targeted Sustainable Development Goals

-

5 new jobs are created, and 8 new client companies increase productivity by up to 30%, driving sustainable growth and competitiveness.

-

17 additional manufacturing companies adopt Dio Smart’s IoT platform, digitalising production and improving efficiency across Kosovo’s industrial sector.

-

15% energy efficiency gains and 20% reduction in machine downtime help manufacturers reduce waste and optimize resource use.

-

A CO₂ monitoring dashboard is developed and launched, helping a total of 23 companies track and lower emissions in their production processes.

News

-

LuxAid Demonstration Fund

Dec. 2025

Dec. 2025Over 1 million euros to supports high-impact business innovations in Kosovo

After the success of the first edition in 2025, the Luxembourg Development Cooperation is launching a new call for proposals aimed at well-established Kosovo-based businesses. The LuxAid Demonstration Fund (LDF) seeks to accelerate the growth and impact of digital and green innovative solutions. Selected projects will receive up to EUR… -

LuxAid Demonstration Fund

Dec. 2025

Dec. 2025Driving Change in Kosovo: How businesses are tackling city congestion and industrial waste

What if the greatest challenges to Kosovo’s future weren’t a shortage of ideas, but the struggle to turn them into reality? Across the country, a new wave of companies is turning real-world problems into scalable products – from easing urban congestion to cutting industrial waste. Among the initiatives supporting this… -

LuxAid Challenge Fund

Nov. 2025

Nov. 2025How businesses from Kosovo are transforming education and manufacturing

In late 2024, Luxembourg’s Development Cooperation launched a new call for proposals under the LuxAid Challenge Fund, a programme designed to support innovative, locally driven solutions to social and economic challenges. Competition was intense: more than 80 applications poured in from across Kosovo, each with bold ideas to tackle the… -

Business Partnership Facility

Sep. 2025

Sep. 2025The BPF, a driver of sustainable business

The Luxembourg State supports the creation of innovative partnerships, inviting the private sector to invest in developing countries. Through the Business Partnership Facility (BPF), Luxembourgish or European companies join forces with foreign partners to generate positive societal impact. Discover in Paperjam the story of e-LMA and Swiss Premium, a win-win… -

Business Partnership Facility

Sep. 2025

Sep. 2025From Luxembourg to Kosovo: Building the finance of tomorrow

Read the interview of Jabir Chakib (CEO of e-LMA) and Ilir Ibrahimi (CEO of Swiss Premium) to have their insight on this BPF-backed project in Kosovo. -

Business Partnership Facility

Sep. 2025

Sep. 2025Launch of the 14th edition of the BPF: Boost your impactful projects in developing countries

Business growth and positive impact? Yes, it’s possible! Whatever your sector, the Business Partnership Facility (BPF) can help your enterprise expand internationally while contributing to a fairer, more inclusive and sustainable future. -

LuxAid Challenge Fund LuxAid Demonstration Fund

Nov. 2025

Nov. 2025Eight bold innovations shaping Kosovo’s future

After months of mobilisation across a vibrant ecosystem and a rigorous selection process, eight groundbreaking projects led by Kosovo-based enterprises have been awarded support through the Luxembourg Challenge Fund (LCF) and the Luxembourg Demonstration Fund (LDF). Launched in late 2024 with a budget of more than EUR 1.5 million, this… -

LuxAid Challenge Fund

Apr. 2025

Apr. 2025LuxAid Challenge Fund: 15 innovative entrepreneurs pitched their projects in Benin

The LuxAid Challenge Fund in Benin has reached a major milestone with the recent Pitch Days held in Cotonou…